Looking to stock up on high-performing power tools? This comprehensive guide dives deep into the world of electric impact drills wholesale, offering invaluable insights for businesses aiming to provide top-notch drills to their customers. Whether you're a DIY retailer, a construction company procuring equipment, or a hardware store owner, understanding the nuances of wholesale power tools like impact drills is crucial. Read on to discover why sourcing electric impact drills at wholesale prices is a smart move and how to choose the best options for your needs.

1. What Exactly is an Electric Impact Drill and Why is it a Must-Have Power Tool?

An electric impact drill, often confused with a standard electric drill or a hammer drill, is a power tool specifically designed for tasks that require significant force, like driving long screws or boring large drill holes into tough materials. Unlike regular drills that rely solely on rotational force, an impact drill uses a hammering action in conjunction with rotation. This impact mechanism delivers short, powerful bursts of force, making it significantly more effective at overcoming resistance.

For businesses catering to professionals or serious DIY enthusiasts, offering impact drills is essential. These tools excel in demanding applications such as construction, decking, and automotive repair. They make quick work of driving screws into dense wood, metal, and even masonry, where a conventional drill might struggle or fail. The added power and efficiency translate to faster project completion and less strain for the user, making them a valuable addition to any power tool lineup.

2. Corded vs. Cordless Impact Drills: Which Drill Type Dominates the Wholesale Market?

Both corded and cordless impact drills have their place in the market, but cordless options are increasingly popular, particularly in the wholesale sector. Cordless impact drills, powered by rechargeable lithium-ion batteries, offer unparalleled cordless convenience and portability. This freedom from power outlets makes them ideal for use in remote locations or on job sites where maneuverability is crucial.

While corded drills offer consistent power without the worry of battery life, the cordless revolution is driven by advancements in battery technology. Modern cordless impact drills often boast comparable power to their corded counterparts, and longer battery life ensures they can handle demanding tasks. For wholesalers and retailers, stocking a variety of cordless models caters to the growing demand for flexible and mobile power tools. Consider offering both, but recognize the strong upward trend of cordless technology. We, as a drill factory made in china, see this trend firsthand.

3. What Key Features Should You Look for When Buying Impact Drills Wholesale?

When selecting impact drills for wholesale, several features significantly impact performance and user satisfaction. Torque, measured in Newton-meters (Nm), indicates the rotational force the drill can deliver. High torque is crucial for driving large fasteners and working with hard materials. The voltage of the battery (for cordless models), such as 24V, also plays a role in power output.

The chuck size, typically 10mm or 13mm, determines the maximum size of the drill bit the drill can accommodate, influencing its versatility. An adjustable clutch is another important feature, allowing users to set the appropriate amount of torque for different applications, preventing overdriving screws. Consider models with variable speed settings for better control and precision. A keyless chuck allows for quick and easy drill bit changes. Finally, the type of motor – brushless or brushed – significantly affects efficiency and lifespan, as we'll discuss later.

4. Durability Matters: How to Choose Electric Impact Drills Built to Last?

Durability is a paramount concern when purchasing power tools, especially for wholesale distribution. Customers expect their drills to withstand regular use and potentially harsh working conditions. Look for impact drills constructed with high-quality materials, such as robust housings and metal gears. Reinforced chucks and sturdy battery connections (for cordless models) contribute to overall robustness.

Consider the reputation of the impact drill manufacturers and suppliers. Companies with a proven track record of producing reliable tools are generally a safer bet. Don't hesitate to inquire about the materials used in construction and any drop or impact resistance testing performed. For instance, our impact drills are designed and built to withstand demanding job site environments. Offering durable tools builds customer trust and reduces warranty claims, ultimately benefiting your business.

5. Versatility is Key: Exploring the Range of Applications for Impact Drills.

The versatility of an impact drill makes it a valuable addition to any toolkit. While primarily designed for driving drive screws and tightening nuts and bolts, they can also handle a variety of drilling tasks. With the appropriate drill bit, an impact drill can drill holes in wood, metal, plastic, and even masonry.

The hammering action is particularly beneficial when working with dense materials or when encountering resistance. This makes them suitable for tasks ranging from assembling furniture and installing shelves to more demanding applications like framing walls and constructing decks. The range of impact drills available caters to different needs, from compact models for tight spaces to heavy-duty versions for professional use. Highlighting this versatility in your product descriptions and marketing materials can attract a wider customer base.

6. Is Ergonomic Design Important When Selecting Wholesale Impact Drills?

Absolutely! Ergonomic design is a crucial factor to consider when selecting wholesale impact drills. Professionals and DIYers alike spend extended periods using these tools, and a poorly designed drill can lead to fatigue, discomfort, and even injuries. Look for drills with comfortable grips, balanced weight distribution, and well-placed controls.

Features like rubber overmolds on the handle reduce vibration and provide a secure grip, even in sweaty or gloved hands. Lightweight designs minimize strain during prolonged use. Consider models with built-in LED lights to illuminate the work area, improving visibility and safety. Ergonomically designed tools not only enhance user experience but also contribute to increased productivity and reduced risk of repetitive strain injuries. This is why ergonomic design is a priority in our R&D process.

7. Finding the Right Wholesaler: What to Consider When Sourcing Electric Impact Drills?

Finding a reliable wholesaler is paramount for sourcing electric impact drills effectively. Consider factors like the wholesaler's reputation, experience in the power tool industry, and the quality of their products. Directly engaging with a drill factory like ours can offer competitive pricing and greater control over the manufacturing process.

Evaluate their ability to meet your order volumes and delivery timelines. Clear and efficient communication is essential. Inquire about their warranty policies and after-sales support. Understanding their payment methods and logistics capabilities is also crucial. Attending exhibitions, as Mark Thompson often does, is a great way to meet potential suppliers face-to-face and assess their offerings firsthand. Don't underestimate the importance of a strong and transparent relationship with your tools supplier.

8. Are Brushless Motors a Game Changer for Cordless Impact Drills in Wholesale?

Yes, brushless motors represent a significant advancement in cordless impact drill technology and are increasingly a key selling point in the wholesale market. Unlike traditional brushed motors, brushless motors don't have carbon brushes, which reduces friction and heat build-up. This leads to several advantages:

- Increased Efficiency: Brushless motors are more energy-efficient, translating to longer battery life and more work per charge.

- Enhanced Power: They often provide more power and torque compared to brushed motors of the same size.

- Extended Lifespan: The absence of friction means less wear and tear, resulting in a longer motor lifespan and improved durability.

- Reduced Maintenance: Without brushes to replace, brushless impact drills require less maintenance.

While brushless models may have a slightly higher initial cost, their long-term benefits and performance advantages make them a compelling option for both professionals and serious DIYers. Stocking cordless impact drills with brushless motors can give your business a competitive edge.

9. Why is Considering Voltage and Torque Crucial When Purchasing Impact Drills Wholesale?

Voltage and torque are fundamental specifications that determine the power and capability of an impact drill. Voltage, typically referring to the rated voltage of the battery in cordless models, directly impacts the tool's overall power. Higher voltage generally equates to more power for demanding tasks.

Torque, as mentioned earlier, is the rotational force the drill can exert. It's crucial for driving large screws, drilling into tough materials, and loosening stubborn fasteners. When purchasing impact drills wholesale, consider the needs of your target customers. Professionals working on heavy-duty construction projects will require drills with higher voltage and torque. DIYers tackling lighter tasks may find lower voltage options sufficient. Offering a range of impact drills with varying voltage and torque settings caters to a broader customer base. Our drills provide a full range of options to meet diverse needs.

When importing electric impact drills, especially from a supplier in a developing country like China, verifying certifications and ensuring quality is paramount. Certifications like CE (European Conformity) and UL (Underwriters Laboratories) indicate that the products meet specific safety and quality standards.

Thorough quality inspection is crucial to avoid issues like defects or non-compliance. Engage in pre-shipment inspections and request documentation verifying the authenticity of certifications. Be wary of occasional certificate fraud by suppliers, as experienced by customers like Mark Thompson. Working with reputable impact drill manufacturers and suppliers who have a proven history of compliance and quality control is essential. Building a strong relationship based on trust and transparency can mitigate these risks.

Key Takeaways:

- Electric impact drills are powerful tools essential for professionals and serious DIYers due to their hammering action that aids in driving fasteners and drilling into tough materials.

- Cordless impact drills are gaining popularity due to their cordless convenience and advancements in battery technology, offering comparable power to corded models.

- Key features to consider when buying impact drills wholesale include torque, voltage, chuck size, adjustable clutch, variable speed, and keyless chuck.

- Durability is crucial; look for drills made with high-quality materials from reputable impact drill manufacturers and suppliers.

- Impact drills offer significant versatility, suitable for a wide range of drilling tasks and fastening applications.

- Ergonomic design is vital for user comfort and safety, reducing fatigue and the risk of injuries.

- Finding a reliable wholesaler with a strong reputation and commitment to quality is essential for successful sourcing.

- Brushless motors offer significant advantages in cordless impact drills, including increased efficiency, power, and lifespan.

- Voltage and torque are critical specifications to consider, aligning the tool's capabilities with the needs of your target customers.

- Thoroughly verify certifications like CE and UL and conduct quality inspections when importing electric impact drills to ensure compliance and avoid fraudulent practices.

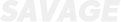

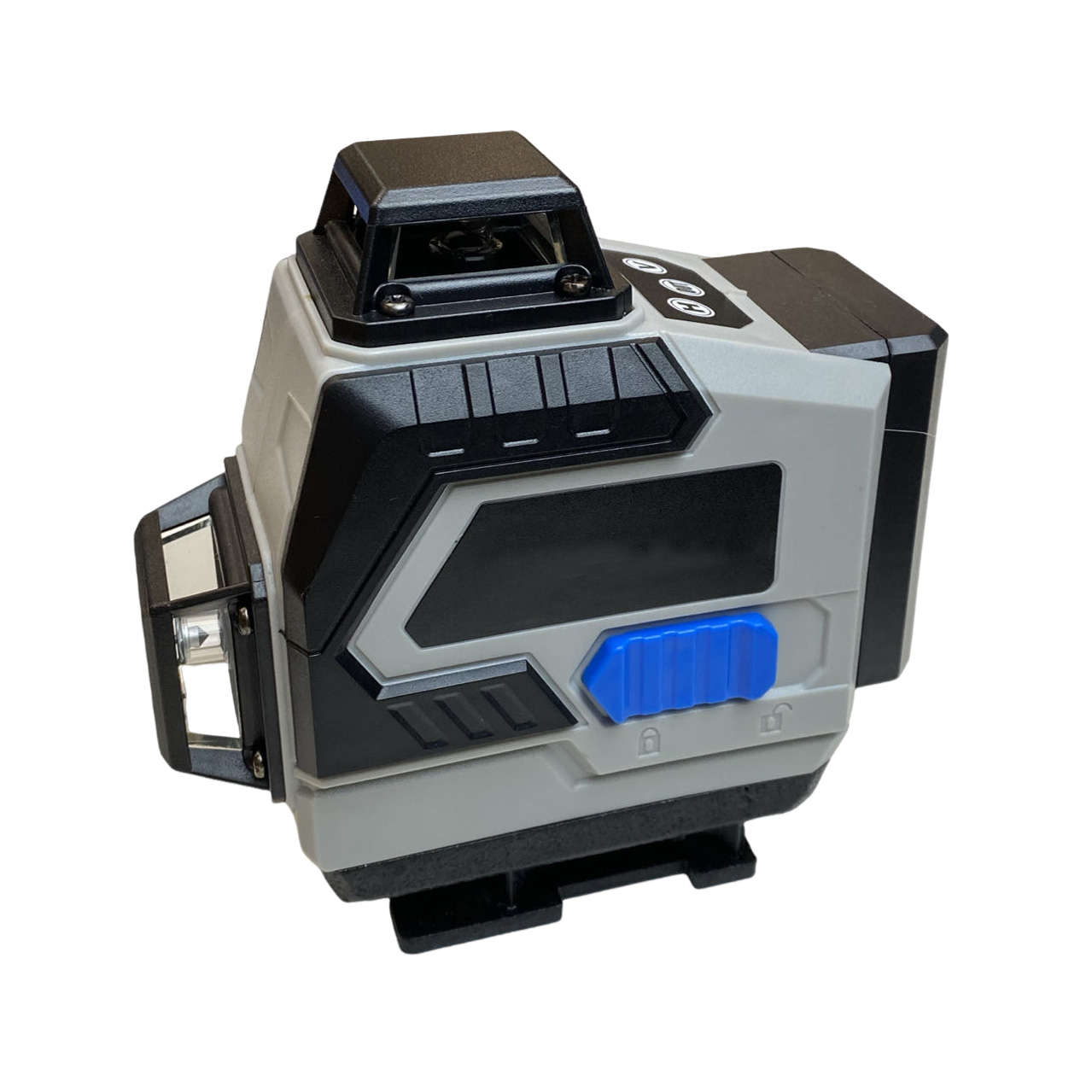

By understanding these key aspects of electric impact drills wholesale, your business can make informed decisions, stock high-quality tools, and meet the demands of your discerning customer base. Consider exploring our cordless lithium power tools like our Cordless Lithium Brushless Drill SG-DN45-BL18 for a powerful and efficient option. For tasks requiring extreme force, our Cordless Lithium Impact Wrench SG-IWN380-BL21 is an excellent choice. We also offer a versatile range of laser levels, such as the Laser Level SG-LL16-MX3, essential for precision work. Remember, choosing the right wholesale power tools is an investment in your business's success.

Post time: 1 月-09-2025